G.E.E.R. - international national

About Us

International orientation

Our wide international network enables exclusive procurement of products from manufacturers of globally patented technologies

Safe energy efficiency

Our goal and motivation is to ensure the efficient use of energy SAFELY.

One with nature

Our technologies have helped numerous companies meet legal requirements for energy efficiency and CO2 emissions

Networking for you

Our international network for your energy

Main services of the G.E.E.R. GmbH

Advice

We advise you on the possible uses of technologies to increase energy efficiency. We also take into account public funding and financing options.

Introduce

G.E.E.R. represents innovative technologies from international manufacturers on the German market - mainly in the area of energy efficiency, but not only.

Implement

We plan the use of our technologies for you and implement them with partners.

Efficiency for environmental protection

With our technologies you can increase the efficiency of your company and save money and emissions

FTR Technology

FTR (Fouling – Thickness – Reflectivity)

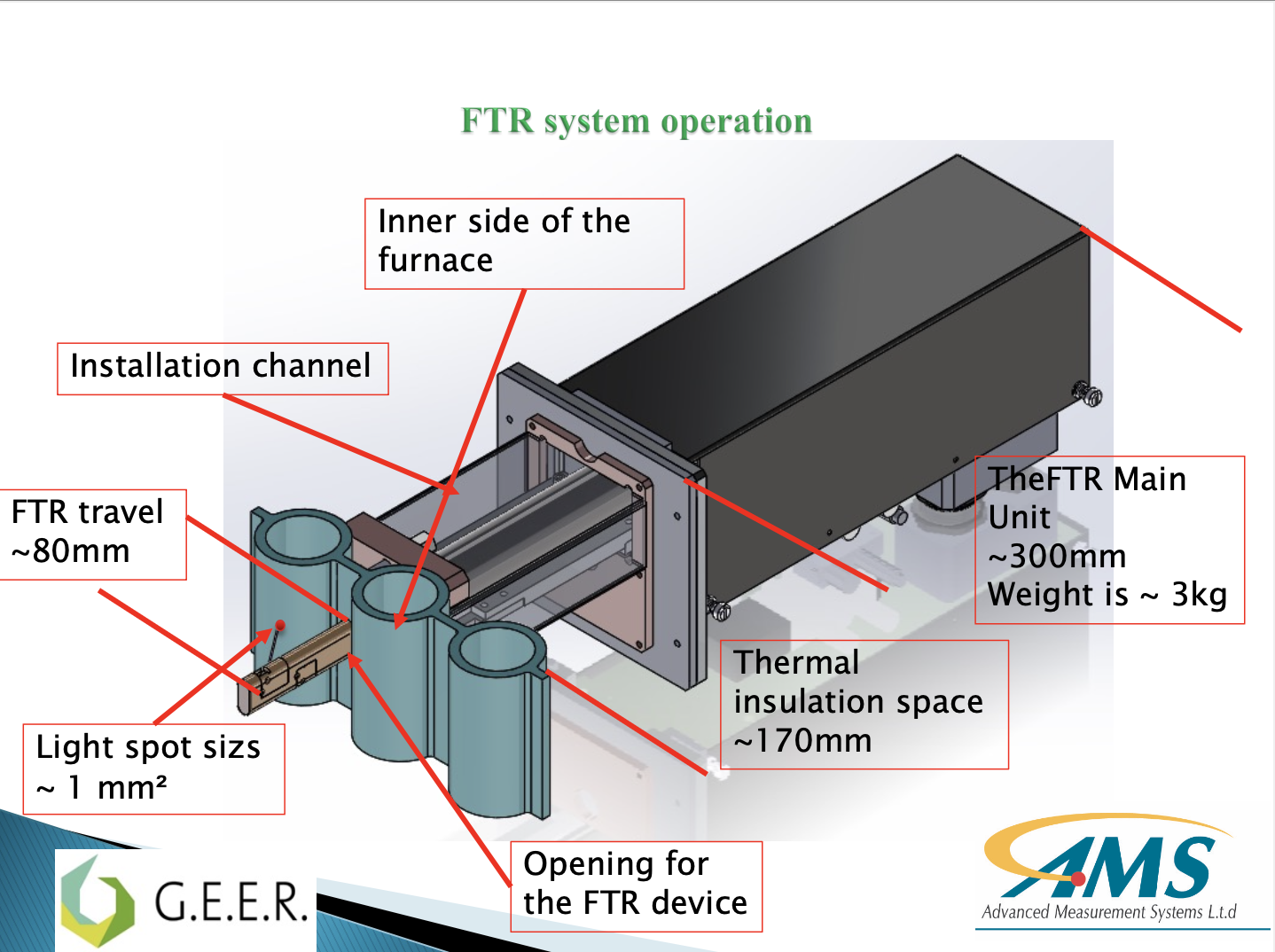

FTR Technology enhances boiler efficiency and increases green energy output by monitoring Fouling Thickness, Reflectivity (FTR), and Flame Temperature within the furnace. Given the rising costs of raw materials and the demand for co-firing coal and biomass, waiste material we anticipate strong market demand for our FTR technology, a laser-based system providing real-time, non-contact measurement of these critical parameters.

- FTR optimizes the boiler cleaning system, prevents forced outages, reduces raw consumption, operational and maintenance costs, evaluates tube erosion, extends the lifespan of boilers at power plants, and enhances green energy generation. The FTR tool provides direct information on the thickness and reflectivity of deposition on the local boiler wall area. It is easy to install, maintenance-free, does not require a cooling system, and can be used on any boiler equipped with a soot blowing system and water lance or cannon.

- The Portable FTR can conduct audits of furnace conditions and boiler efficiency, shedding light on your entire block of identical boilers. The FTR system is being evaluated for new and advanced applications by the Institute of Combustion and Power Plant Technology (IFK) at Stuttgart University in Germany, in close cooperation with G.E.E.R. GmbH, Berlin, Germany, and AMS Ltd, Israel.

- FTR can significantly aid the shift from coal to alternative and renewable energy sources by offering expertise and support. This transition is vital for reducing environmental harm and fostering a sustainable energy future. Through FTR's assistance, stakeholders can navigate this complex process efficiently, contributing to global climate efforts and renewable energy adoption.

Optimization of heat transfer

With our technology, determining contamination thickness and reflection properties becomes child's play

Our commitment is convincing internationally

What makes FTR different?

Measurement of all data to determine the optimal procedure for cleaning the boiler system. FTR can optimize the cleaning process and improve heat transfer within the furnace, thereby increasing boiler efficiency, reducing maintenance costs and carbon emissions, and predicting erosion.

Collection of the aforementioned real-time data

Monitoring of the final combustion chamber temperature (FEGT)

FTR - your eyes in the boilers of biomass and coal-fired power plants.

Monitoring local heat transfer

Cleanliness Factor (CF) monitoring

FTR - the optimal boiler cleaning technology is patented in the USA and Europe.

For the environment

How FTR works?

It has been shown that two different types of deposits form during operation. A type with a small layer thickness and continuous growth and another type in which large conglomerates of unburned material form when they hit the walls and are then removed again after a relatively short time by turbulent gas flows inside the boiler.

A comparison of the pollution dynamics was carried out for different types of coal carried out. It has been shown that the effects of the contamination reflection on the final combustion chamber temperature (FEGT) and the cleanliness factor (CF) are just as important as the contamination thickness or that the contamination reflection may even have a STRONGER effect than the contamination thickness. Basically, the procedure and mode of operation in biomass power plants is the same.

A comparison of the pollution dynamics was carried out for different types of coal carried out. It has been shown that the effects of the contamination reflection on the final combustion chamber temperature (FEGT) and the cleanliness factor (CF) are just as important as the contamination thickness or that the contamination reflection may even have a STRONGER effect than the contamination thickness. Basically, the procedure and mode of operation in biomass power plants is the same.

Cost efficient

Improving efficiency - reducing fuel consumption

Optimized cleaning activation - reducing the overall cost of compressed air

Reduction of

erosion - extension of boiler running time

erosion - extension of boiler running time

Easier and cheaper maintenance due to less erosion of water pipes and less frequent use of soot blower equipment

Reduced emissions

Reduction of CO2, SO2 and other pollutant emissions from fuels through improved efficiency

Less NOx by reducing the final combustion chamber temperature (FEGT)

G.E.E.R.

Partnerships

Partnerships

G.E.E.R. is strategic partner of AMS Ltd.

Phone

+49/30/83-22-33-43

office@geerweb.eu

Address

Kurfürstenstraße 56,

10785 Berlin, Deutschland

10785 Berlin, Deutschland